Introduction to the causes of damage to the lining of the electric furnace

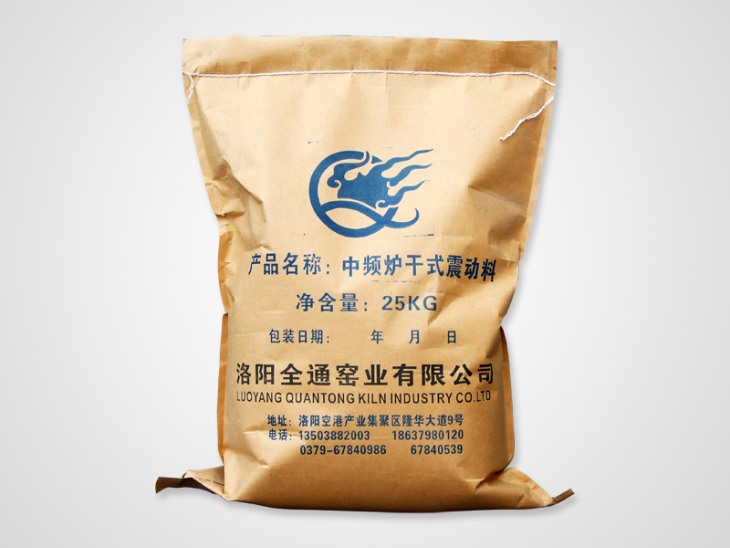

Furnace liningIt is a coreless intermediate frequency induction furnace suitable for iron and steel plants, foundries and metal manufacturing. It needs to supply high temperature resistant lining materials when firing the furnace. It has strong properties, high flexibility, strong impact resistance, high softening temperature under load, high high temperature compressive strength, high high temperature flexural strength, and good slag resistance, especially suitable for intermittent operation of large intermediate frequency induction furnaces. You understand why the lining of the electric furnace is damaged:

1. The penetration of molten iron destroys the penetration of molten iron into the carbon brick along the pores of the carbon brick. The infiltrated molten iron dissolves the binder in the carbon brick, and then dissolves the carbon particles in the carbon brick, destroys the compactness of the carbon brick, and reduces the carbon brick. The molten iron infiltrated into the carbon brick reacts with the carbon brick to form a brittle substance like FexC. The hot surface of the carbon brick forms an embrittlement layer.

2, the circulation of molten iron in the furnace

The circulation of molten iron aggravates the erosion and abrasion of the brittle layer on the surface of the carbon brick by molten iron, which makes the carbon brick thinner. It is strongly eroded by the flowing slag and iron, thereby reducing the life of the furnace lining.

3. Corrosion of carbon bricks by alkali metals and zinc

Thermodynamic calculations show that when the heat transfer performance of the carbon brick is poor, there is a large temperature difference between the hot surface and the cold surface, and the thermal stress of the temperature difference inside the carbon brick is large, which induces cracks in the carbon brick, and pure alkali metal vapor passes through the carbon brick. The micro-cracks of the carbon bricks continuously flow and spread to the low temperature area of the carbon brick, and the micro-cracks are the cause of ring cracks. If the alkali metal vapor enters the micro-cracks of the carbon brick, when the temperature reaches 800 degrees Celsius, the alkali metal vapor will be in the micro-cracks. Liquefaction, and then react with the silica-alumina ash of the carbon brick, causing the volume of the ash to expand by 30%, aggravating the expansion of micro-cracks in the carbon brick and forming cracks.

Luoyang Quantong Kiln Industry Co., Ltd. is a comprehensive high-tech company integrating R&D, production, sales and construction services. It is a high-tech enterprise in Henan Province and an IS09001 quality assurance system certification enterprise. The company serves large and medium-sized circulation in the power industry. Fluidized bed boiler, the main materials are: high-strength wear-resistant refractory castables, wear-resistant corundum plastics, self-flow wear-resistant corundum castables, medium-heavy and slightly expanded plastics, lightweight thermal insulation concrete, high-performance high-alumina castables , high-temperature binder, high-temperature cement and plastering materials, various ramming materials, high-strength wear-resistant corundum bricks, ladle breathable bricks, silicon carbide bricks, intermediate frequency furnace linings, special-shaped wear-resistant refractory bricks, thermal insulation bricks, etc. 20 series more than 160 A variety of unshaped products and shaped products, the products sell well in all provinces, municipalities and autonomous regions across the country and overseas.

Related News

- Introduction of construction method of ramming material in intermediate frequency furnace

- How to choose the material of furnace lining

- The difference between rammer and castable

- Application direction of intermediate frequency furnace refining

- Introduction to the construction method of dry ramming material

- Do you know the production process and control points of breathable bricks?

- The application of argon blowing technology at the bottom of the intermediate frequency furnace

- Method for prolonging service life of intermediate frequency furnace lining

- In addition to diffused breathable bricks, there are those types of breathable bricks

- What are the advantages of coil cement

- Introduction of remedies for cracks in ramming material

- Difference analysis between dry and wet charging of intermediate frequency furnace charge

- What are the methods to improve the success rate of ladle blowing with argon

- Introduction to the difference between dry vibrating material and ramming material

- Analysis of the characteristics of diffused breathable bricks

- What are the good coil glues?

- Furnace lining manufacturers tell you the steps of the oven

- What should be paid attention to in the knotting process of wear-resistant ramming material

- Refractory manufacturers tell you the reason for the damage to the boiler lining

- Introduction to the method of improving the argon blowing rate of ladle permeable bricks