Introduction to the role of carbon ramming material

carbonramming materialIt is a kind of ramming material. According to different blast furnace types and different material design requirements, carbon ramming material is mainly used between the carbon bricks at the bottom of the blast furnace and the bottom sealing plate and between the carbon bricks in the hearth and the cooling stave. As well as the leveling above the center line of the bottom water cooling tube and the filling of the cooling wall, all parts require that the carbon ramming material after ramming material has a certain strength and density, filling every corner and small gap. , to meet the requirements of no leakage of molten iron and gas, and the thermal conductivity of the carbon ramming material should be basically consistent with the performance of the blast furnace hot carbon bricks and cooling stave, so as not to affect the life of the blast furnace, so as to maintain the normal production of the blast furnace.

The problem often encountered in the use of carbon ramming materials is that the thermal conductivity of general carbon ramming materials is low, which is not conducive to the rapid cooling of the blast furnace body, thus affecting the service life. Therefore, the update research and development of carbon ramming materials with high thermal conductivity The application has great market prospects. Whether it is adding additives to the carbon ramming material, changing the properties of the material through in-situ reaction at high temperature, or changing the structure of the local material from the design point of view, so that the carbon ramming material layer increases in working temperature. When the temperature is high, the thermal conductivity can be matched with the carbon bricks and cooling stave to ensure the normal heat conduction without damaging the overall construction structure, so as to meet the requirements of improving the life of the blast furnace.

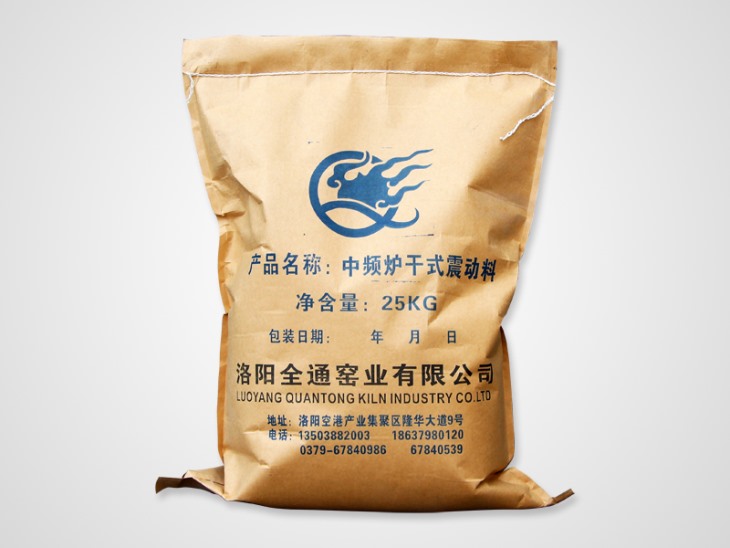

Luoyang Quantong Kiln Industry Co., Ltd. is a comprehensive high-tech company integrating R&D, production, sales and construction services. It is a high-tech enterprise in Henan Province and an IS09001 quality assurance system certification enterprise.

The company serves large and medium-sized circulating fluidized bed boilers in the power industry. The main materials are: high-strength wear-resistant refractory castables, wear-resistant corundum plastics, self-flow wear-resistant corundum castables, medium-heavy and micro-expandable plastics, lightweight thermal insulation Concrete, high-performance high-alumina castables, high-temperature binders, high-temperature cement and plastering materials, various ramming materials, high-strength wear-resistant corundum bricks, ladle breathable bricks, silicon carbide bricks, intermediate frequency furnace linings, special-shaped wear-resistant refractory bricks, There are more than 160 kinds of amorphous products and shaped products in 20 series such as thermal insulation bricks, and the products sell well in all provinces, municipalities, autonomous regions and overseas. At the same time, the company has established a strong construction team to ensure the high-quality use of the products.

Related News

- Introduction of construction method of ramming material in intermediate frequency furnace

- How to choose the material of furnace lining

- The difference between rammer and castable

- Application direction of intermediate frequency furnace refining

- Introduction to the construction method of dry ramming material

- Do you know the production process and control points of breathable bricks?

- The application of argon blowing technology at the bottom of the intermediate frequency furnace

- Method for prolonging service life of intermediate frequency furnace lining

- In addition to diffused breathable bricks, there are those types of breathable bricks

- What are the advantages of coil cement

- Introduction to the use performance of breathable bricks

- Some points that should be paid attention to in the furnace lining construction of the intermediate frequency furnace

- What are the advantages of qualified intermediate frequency furnace linings?

- Cause Analysis of Damaged Furnace Lining

- Introduction of chemical erosion of ramming material in intermediate frequency furnace

- Introduction to the construction method of smearing ramming material

- How to improve the argon blowing rate of ladle breathable bricks

- The correct operation plan of the ramming material used in the bottom of the electric furnace

- What is the material of the intermediate frequency furnace lining

- How to remedy cracks in ramming material