What are the advantages of qualified intermediate frequency furnace linings?

Refractory materials for intermediate frequency furnaces are divided into three types: acid, neutral and alkaline according to their properties. According to the construction method, they are divided into dry ramming material, wet ramming material, castable material, coating material, etc. In general, common The main raw material of furnace lining material includes quartz matrix, based on the lining material mixed with quartz sand material, the raw material is high purity, the material ratio is reasonable, the corrosion resistance of molten iron is enhanced, the resistance to cold and heat is strong, the softness is high, the impact resistance is strong, and the load softening temperature High, high temperature compressive strength, high temperature flexural strength, good slag resistance, especially suitable for intermittent operation of large medium frequency induction furnace.

However, not all intermediate frequency furnacesFurnace liningAll can successfully complete the task under the action of high temperature, which requires strict requirements for materials from various aspects to ensure that there will be no problems in the process. In the process of reproduction of many manufacturers, in order to save costs, they will automatically It is not advisable to prepare raw materials, resulting in problems such as wear through the furnace and low furnace age during the use process, the output will not come up, and the electric furnace will be seriously damaged.

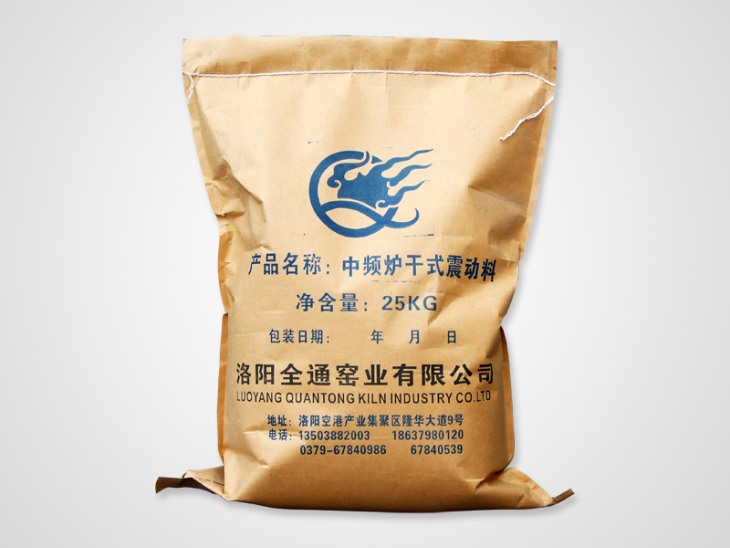

So, what kind of furnace lining material is qualified and excellent? What are the advantages of the truly qualified intermediate frequency furnace lining material or what needs to be guaranteed? Today, the editor of Quantong Kiln Industry will give you a detailed arrangement List them.

1. Selected raw materials

The quality of raw materials requires high requirements, select raw materials, ensure high purity of raw materials, and ensure stable product quality.

2, the effect is stable

The material is based on the mixing of high-density quartz sand, adding part of fused silica, pre-phase-change treated quartz, high temperature resistant binder, anti-quenching and rapid-heating stabilizer, anti-seepage agent, anti-cracking agent and other composite micropowder materials. It has the characteristics of strong resistance to molten iron corrosion, no cracking and slow loss, which successfully overcomes many disadvantages of traditional furnace lining materials.

3, temperature resistant

The temperature resistance needs to be suitable for the melting degree of 1400 degrees Celsius - 1780 degrees Celsius.

4, the construction is convenient

This material is a pre-mixed dry ramming mixture, and the content of sintering agent and mineralizer has been prepared according to the needs of customers. Users can directly dry vibrate or ram it into use without adding any materials.

5, furnace age

Under the operating conditions, continuous use, smelting gray iron, pig iron, ductile iron and other cast iron materials, the normal lining usage times can reach more than 500 heats; and the normal lining life of smelting ordinary carbon steel, high carbon steel, high chromium steel can reach 195 The furnace lining life can be increased by more than 50% compared with traditional products.

6, economical and durable

The 70-ton intermediate frequency steelmaking furnace with high output is 35-60 furnaces, the 40-ton intermediate-frequency steel-making furnace is 40-70 furnaces, and the 1-ton intermediate frequency casting furnace is 300-600 furnaces (reference value).

To sum up, as long as the above 6 characteristics are possessed, in the process of use, the common problems such as easy cracking, furnace wall erosion, low furnace age, and low output can be well avoided.

Related News

- Introduction of construction method of ramming material in intermediate frequency furnace

- How to choose the material of furnace lining

- The difference between rammer and castable

- Application direction of intermediate frequency furnace refining

- Introduction to the construction method of dry ramming material

- Do you know the production process and control points of breathable bricks?

- The application of argon blowing technology at the bottom of the intermediate frequency furnace

- Method for prolonging service life of intermediate frequency furnace lining

- In addition to diffused breathable bricks, there are those types of breathable bricks

- What are the advantages of coil cement

- Cause Analysis of Damaged Furnace Lining

- Introduction of chemical erosion of ramming material in intermediate frequency furnace

- Introduction to the construction method of smearing ramming material

- How to improve the argon blowing rate of ladle breathable bricks

- The correct operation plan of the ramming material used in the bottom of the electric furnace

- What is the material of the intermediate frequency furnace lining

- How to remedy cracks in ramming material

- Introduction to the solution to cracks in the ramming material of the intermediate frequency furnace

- What are the advantages of using coil cement

- What kind of furnace lining is qualified