Introduction to the composition structure and function of ramming material

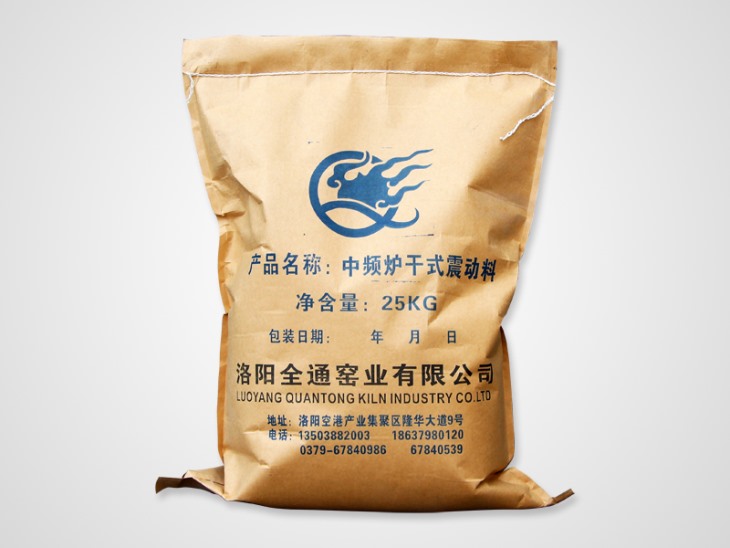

Today, Luoyang Quantong Kiln Industry Co., Ltd. will take you to understand the composition and function of the ramming material:

The ramming material uses magnesium chloride, sulfate and other aqueous solutions, as well as phosphates and their polymers as binders, and also often uses higher carbon-containing organics and temporary binders that form carbon bonds at high temperatures. Chromium Glauber's salt is often used as a binder for ramming materials. High-alumina and corundum ramming materials are often used as binders with inorganic substances such as phosphoric acid and aluminum phosphates, chlorides, and sulfates. Due to the reaction between phosphoric acid and activated alumina in the ramming material, the formation of water-insoluble aluminum orthophosphate deposits and agglomeration and hardening. To prolong the shelf life of the ramming material, it is necessary to add appropriate preservatives to prevent or delay the agglomeration and hardening. Generally, oxalic acid is used as a preservative.

The function of the ramming material Generally, the ramming material is mainly used for the parts that are in direct contact with the molten material. It is required that the refractory material must have excellent volume stability, fineness and erosion resistance, so high temperature firing or electrofusion raw materials are generally used. The particle size of the ramming material is related to the use part and the construction method. Most of the ramming materials have low normal temperature strength before sintering, and some are not high in medium temperature strength. An excellent combination was then achieved.

The refractory performance of quartz sand ramming material has been indicated by a large number of production and use data, the function is more stable, and the advantages of use are remembered, and through the accurate ratio of materials and auxiliary materials, the waste of production materials is greatly reduced and production consumption is saved. The ramming material has high stability and corrosion resistance at high temperature.

Luoyang Quantong Kiln Industry Co., Ltd. is a comprehensive high-tech company integrating R&D, production, sales and construction services. It is a high-tech enterprise in Henan Province and an IS09001 quality assurance system certification enterprise.

Facing the market demand and the hope of customers, the company is committed to developing all kinds of high-tech amorphous refractory materials and products independently and cooperatively, and try its best to expand its application fields.

Related News

- Introduction of construction method of ramming material in intermediate frequency furnace

- How to choose the material of furnace lining

- The difference between rammer and castable

- Application direction of intermediate frequency furnace refining

- Introduction to the construction method of dry ramming material

- Do you know the production process and control points of breathable bricks?

- The application of argon blowing technology at the bottom of the intermediate frequency furnace

- Method for prolonging service life of intermediate frequency furnace lining

- In addition to diffused breathable bricks, there are those types of breathable bricks

- What are the advantages of coil cement

- Instructions for use of diathermy furnace knotting material

- What should I do if the intermediate frequency charge is knotted?

- What kind of furnace lining is qualified

- Analyze the benefits of using coil cement

- How to Correctly Repair Intermediate Frequency Furnace Lining

- What raw materials can be used for breathable brick products

- How to remedy the problem of cracks in the ramming material

- What kind of furnace lining is good

- Furnace lining manufacturers teach you what are the steps of the oven

- Maintenance tips for intermediate frequency furnace lining