What kind of furnace lining is good

The quality of the material is directly related to the furnace and affects the use. Therefore, the requirements for the furnace lining material also have a certain degree of rigor. What are the points of all good furnace linings:

\u003Ci>一.\u003C\/i> \u003Cb>one.\u003C\/b>\u003Ci>稳定性炉料的化学功能和物理机制,关乎着中频电炉对高温熔炼工作.炉料的制造上化学各项功能必需符合冶炼金属的化学特性.使得炉料在使用中具有耐腐蚀,耐冲刷,抗渣性等必备元素.\u003C\/i> \u003Cb>The chemical function and physical mechanism of the stable charge are related to the high-temperature smelting work of the intermediate frequency electric furnace. The chemical functions of the charge must conform to the chemical properties of the smelted metal. The charge has corrosion resistance, erosion resistance, and slag resistance in use. and other necessary elements.\u003C\/b>

\u003Ci>2.\u003C\/i> \u003Cb>2.\u003C\/b>\u003Ci>耐高温金属简直都处于高温下才方可熔化,而每一种的金属的熔点都不一,大致都在1400 摄氏度以上.所以,选用的炉料必需是具有非常强的耐高温功能.\u003C\/i> \u003Cb>High temperature-resistant metals can only be melted at high temperatures, and the melting point of each metal is different, generally above 1400 degrees Celsius. Therefore, the selected charge must have very strong high temperature resistance.\u003C\/b>

\u003Ci>3.\u003C\/i> \u003Cb>3.\u003C\/b>\u003Ci>耐用性炉衬材料在高温工作下,免不了对自身材料的损耗和腐蚀,炉料在制造上对这个也很有考究的.\u003C\/i> \u003Cb>Durable furnace lining materials will inevitably wear and corrode their own materials under high temperature work, and the furnace charge is also very elegant in manufacturing.\u003C\/b>

\u003Ci>4.\u003C\/i> \u003Cb>4.\u003C\/b>\u003Ci>经济性炉料作为中频感应电炉里面的必消耗品,而每打一次炉能烧多少炉,关系着材料本身的成本和工人施工,挑选材料时必需在性价性上做一个明确挑选.\u003C\/i> \u003Cb>The economical charge is a necessary consumable in the medium frequency induction furnace, and how many furnaces can be fired each time is related to the cost of the material itself and the construction of the workers. When selecting materials, a clear choice must be made in terms of cost performance.\u003C\/b>

\u003Ci>5.\u003C\/i> \u003Cb>5.\u003C\/b>\u003Ci>产出比炉衬尽管仅仅做为一个载体,但是它的功能直接影响着单筑次,能产出多少数.\u003C\/i> \u003Cb>Although the output ratio of the furnace lining is only used as a carrier, its function directly affects how many times a single building can be produced.\u003C\/b>

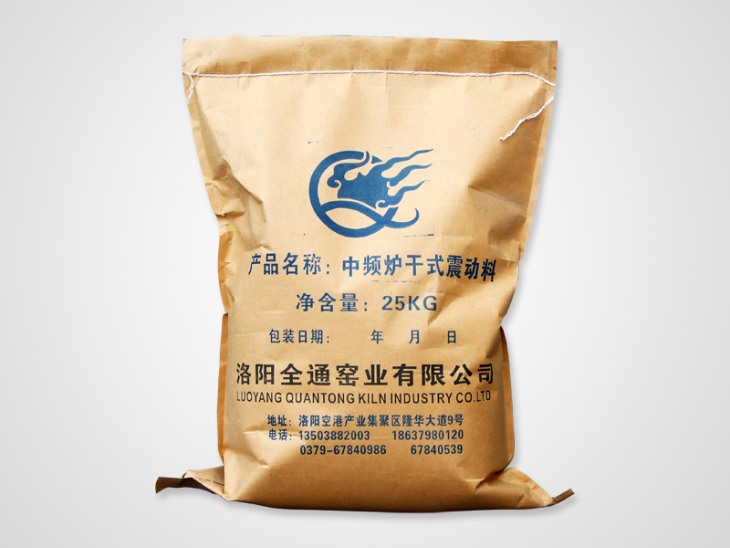

Quotong Kiln serves large and medium-sized circulating fluidized bed boilers in the power industry. The main materials are: high-strength wear-resistant refractory castables, wear-resistant corundum plastics, self-flow wear-resistant corundum castables, medium-heavy and slightly expanded plastics , Lightweight thermal insulation concrete, high-performance high-alumina castables, high-temperature binders, high-temperature cement and plastering materials, various ramming materials, high-strength wear-resistant corundum bricks, ladle breathable bricks, silicon carbide bricks, intermediate frequency furnace linings, special-shaped resistant Abrasive refractory bricks, thermal insulation bricks and other 20 series of more than 160 kinds of amorphous products and shaped products, the products are sold well in various provinces, municipalities, autonomous regions and overseas. The company has set up a strong construction team to ensure the high-quality use of the products.

Related News

- Introduction of construction method of ramming material in intermediate frequency furnace

- How to choose the material of furnace lining

- The difference between rammer and castable

- Application direction of intermediate frequency furnace refining

- Introduction to the construction method of dry ramming material

- Do you know the production process and control points of breathable bricks?

- The application of argon blowing technology at the bottom of the intermediate frequency furnace

- Method for prolonging service life of intermediate frequency furnace lining

- In addition to diffused breathable bricks, there are those types of breathable bricks

- What are the advantages of coil cement

- Furnace lining manufacturers teach you what are the steps of the oven

- Maintenance tips for intermediate frequency furnace lining

- What are the requirements for the use of induction furnace linings?

- What are the precautions for knotting of wear-resistant ramming materials?

- What are the main advantages of using dry ramming material?

- How to maintain the intermediate frequency furnace charge

- What kind of material is suitable for making breathable bricks

- What kind of coil glue is good

- The difference between dry vibrating material and ramming material

- What kind of coil glue is good