What are the requirements for the use of induction furnace linings?

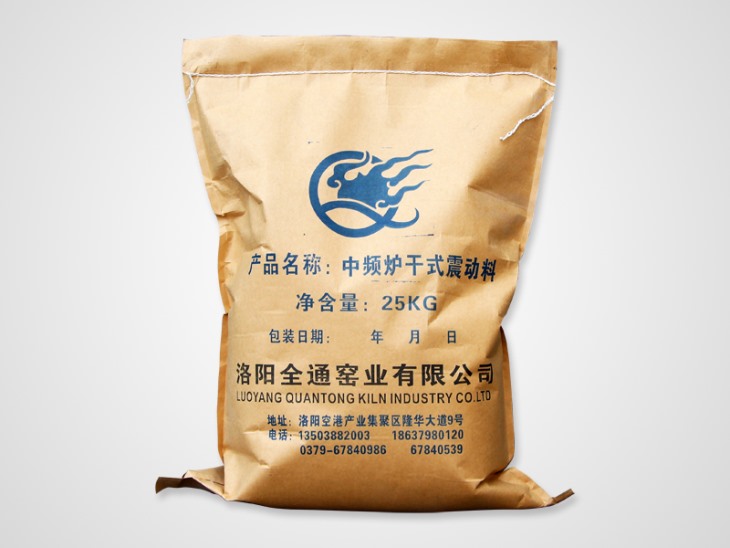

Today, Luoyang Quantong Kiln Industry Co., Ltd. will take you to understand the basic requirements of induction furnace lining materials:

(1) There should be sufficient refractoriness. The refractoriness of the furnace lining material for melting cast iron should be greater than 1650-1700 degrees Celsius, and the softening temperature should be higher than 1650 degrees Celsius;

(2) Good chemical stability, not hydrolyzed and decomposed at low temperature, difficult to decompose and recover at high temperature, and not easy to produce physicochemical reactions in metal alloy liquid, slag, additives, etc., and produce metallurgical reactants during the smelting process;

(3) The thermal stability is good, the coefficient of thermal expansion is small, the temperature of the furnace lining is constantly changing, there is no crack due to uneven heating, the volume should be stable, and there is no severe expansion and contraction to deform the furnace lining;

(4) Good mechanical properties, can withstand the impact of charge charging at low temperature, and can accept the pressure of alloy liquid and intense electromagnetic stirring effect at high temperature. Under the continuous scouring effect of alloy liquid, it can be wear-resistant and heat-resistant erosion;

(5) Good insulation performance, the furnace lining material can withstand the impact of charging charging at low temperature, and can withstand alloy pressure and intense electromagnetic stirring effect at high temperature. Under the continuous scouring effect of alloy liquid, it can be wear-resistant and heat-resistant erosion;

(6) Good knotting performance, easy repair and sintering performance, convenient knotting and maintenance, and furnace lining materials should be readily available in the market.

To meet the above basic requirements can be regarded as induction furnace lining materials

Luoyang Quantong Kiln Industry Co., Ltd. is a comprehensive high-tech company integrating R&D, production, sales and construction services. The company serves large and medium-sized circulating fluidized bed boilers in the power industry. The main materials are: high-strength wear-resistant refractory castables , Wear-resistant corundum plastics, self-flow wear-resistant corundum castables, medium-heavy and slightly expanded plastics, lightweight thermal insulation concrete, high-performance high-alumina castables, high-temperature binders, high-temperature cement and plastering materials, various Ramming materials, high-strength wear-resistant corundum bricks, ladle breathable bricks, silicon carbide bricks, intermediate frequency furnace linings, special-shaped wear-resistant refractory bricks, thermal insulation bricks, etc. 20 series of more than 160 kinds of unshaped products and shaped products, the products sell well in various provinces, municipalities and autonomous regions and Overseas. The company has set up a strong construction team together to ensure the high-quality use of the product. Welcome to inquire.

Related News

- Introduction of construction method of ramming material in intermediate frequency furnace

- How to choose the material of furnace lining

- The difference between rammer and castable

- Application direction of intermediate frequency furnace refining

- Introduction to the construction method of dry ramming material

- Do you know the production process and control points of breathable bricks?

- The application of argon blowing technology at the bottom of the intermediate frequency furnace

- Method for prolonging service life of intermediate frequency furnace lining

- In addition to diffused breathable bricks, there are those types of breathable bricks

- What are the advantages of coil cement

- What are the precautions for knotting of wear-resistant ramming materials?

- What are the main advantages of using dry ramming material?

- How to maintain the intermediate frequency furnace charge

- What kind of material is suitable for making breathable bricks

- What kind of coil glue is good

- The difference between dry vibrating material and ramming material

- What kind of coil glue is good

- Analysis of the use characteristics of diffused ventilation bricks

- What are the specific functions of the use of carbon ramming materials?

- Will the furnace lining affect the furnace temperature of the copper alloy?