Introduction to the difference between ramming material and castable material

Ramming materials and castables are both refractory materials and are widely used, but there are still differences between the two:

1, the difference of raw materials:ramming materialIt is mainly composed of aggregates and powders with a certain particle gradation plus binder and additives, which are mainly made of artificial or mechanical ramming construction. The ramming materials include corundum ramming materials, high aluminum ramming materials, carbonized Silicon ramming material, carbon ramming material, siliceous ramming material, magnesia ramming material like electric furnace bottom ramming material are made of silicon carbide, graphite, electric calcined anthracite as raw materials, mixed with a variety of superfine powder additives, A bulk material body made of fused cement or composite resin as a binder. It is used to fill the furnace body cooling equipment and the masonry gap or the filling material for the masonry leveling layer. Castable is a kind of refractory material added with a certain amount of combined Granular and powdery materials made of castables. It has high fluidity and is suitable for unshaped refractories formed by pouring. The three major components of the castable are the main components, and the three additional components and impurities are divided into: bone materials, powders and binders. The raw materials of aggregates are silica, diabase, andesite and alabaster.

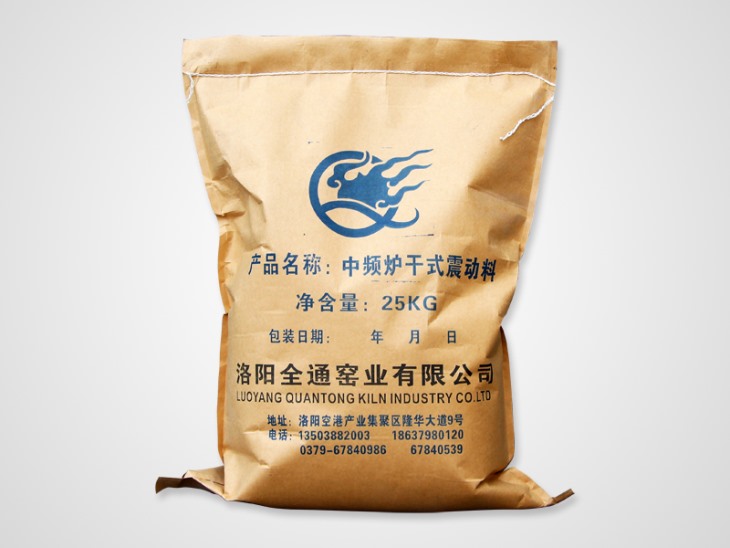

2. The difference between the applicable range of construction: when the ramming material is used for ramming construction, Luoyang Quantong Kiln Industry (ramming material manufacturer) recommends that attention must be paid to uniform force and smooth construction. The ramming material is generally used for refractory brick masonry. The construction of the ramming material is relatively simple, and it is used to fill the gap between the body cooling equipment and the masonry or the filler for the leveling layer of the masonry.

The castable is mainly used to construct the lining of various heating furnaces and other integral structures. Some high-quality varieties can also be used in smelting furnaces. For example, aluminate cement refractory castables can be widely used in various heating furnaces and other slag-free, acid-free In thermal equipment eroded by alkali. In the parts that are eroded by molten iron, molten steel and slag and have a higher working temperature, such as tapping grooves, ladles and

For blast furnace shafts, tapping trenches, etc., refractory castables made of high-quality granular and powdery materials with high alumina content and good sintering combined with low-calcium and pure high-alumina cement can be used. Another example is phosphate refractory castables. Castables can be widely used in heating furnaces and soaking furnaces for heating metals, as well as in coke ovens and cement kilns that are in direct contact with materials. In metallurgical furnaces and other containers that are in direct contact with slag and molten metal Some parts of the furnace are also repaired with high-quality phosphate refractory castables. To sum up, the castables can be used for the casting and molding of key parts of the furnace body, such as the furnace door frame, near the feeding port; the molten metal pouring runner is generally used for pouring The castable is cast and formed, after a period of use, the castable will fall off and need to be repaired regularly.

Related Industry Knowledge

- Features and Benefits of Coil Clay

- What are the advantages of a good furnace lining

- Misunderstandings in the use of ramming materials in intermediate frequency furnaces

- Phenomenon analysis of failure of argon blowing of ladle permeable bricks and how to improve the rate of argon blowing

- Where is the consumption reduction and energy saving of breathable bricks reflected?

- How to improve the service life of intermediate frequency furnace lining

- Reasons for damage to intermediate frequency furnace lining and how to solve them

- The performance and advantages of breathable brick

- Analysis of Structural Characteristics of Dispersive Breathable Bricks

- The intermediate frequency furnace charge knotting process needs to pay attention to details sharing

- Do you know how the breathable brick is damaged?

- How to choose zirconium ramming material for glass kiln bottom

- Matters needing attention in the knotting process of wear-resistant ramming material

- How to use electric furnace lining to repair electric furnace

- Ramming material manufacturers tell you the influence of sliding nozzle refractories on breakout

- What should be paid attention to in material selection of intermediate frequency furnace charge

- Introduction to the construction of furnace lining ramming material

- What material is used for the lining of the intermediate frequency furnace?

- What reasons will affect the service life of the intermediate frequency furnace lining?

- What should be paid attention to in material selection of intermediate frequency furnace charge