What material is used for the lining of the intermediate frequency furnace?

The intermediate frequency furnace lining material is also called intermediate frequency furnace charging material, intermediate frequency furnace dry vibration material, intermediate frequency furnace dry blasting material, intermediate frequency furnace ramming material, etc. It is divided into acidic, neutral and basic furnace lining materials. Acid furnace lining materials are made of high-purity quartz, Fused silica is the main raw material, compound additive is used as sintering agent; neutral furnace lining is made of alumina, high alumina material as the main raw material, compound additive is used as sintering agent; basic furnace lining is high-purity fused corundum, high-purity Fused magnesia and high-purity spinel are used as the primary raw materials, and composite additives are used as sintering agents.

Alkaline furnace lining: It is mainly used for melting all kinds of high alloy steel, carbon steel, high manganese steel, high chromium steel, tool steel, stainless steel and other alloy steels.

Acid lining: Mainly used for the working lining of coreless induction furnaces for melting and holding cast iron.

Acid, neutral and basic furnace linings are widely used in coreless intermediate frequency furnaces and cored induction furnaces, as intermediate frequency furnace lining materials for melting gray cast iron, ductile iron and cast iron alloys, melting carbon steel, alloy steel, high manganese Steel, tool steel, heat-resistant steel, stainless steel, molten aluminum and its alloys, molten copper, brass, cupronickel and bronze and other copper alloys.

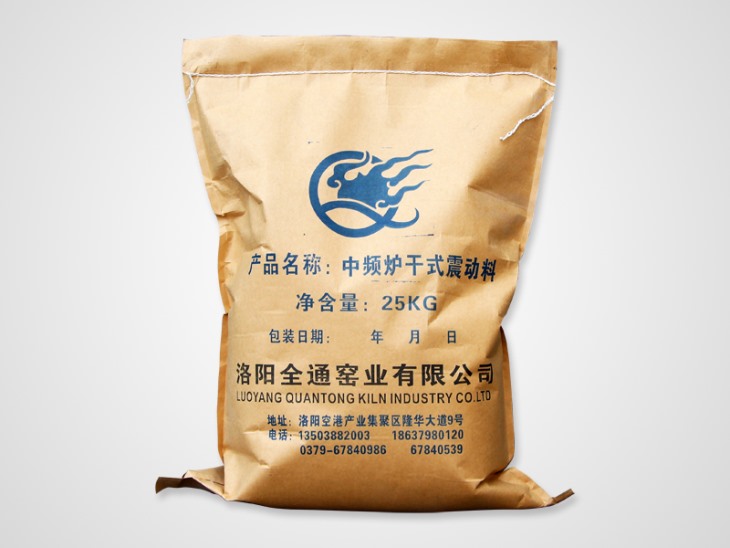

Luoyang Quantong Kiln Industry Co., Ltd. is a comprehensive high-tech company integrating R&D, production, sales and construction services. It is a high-tech enterprise in Henan Province and an IS09001 quality assurance system certification enterprise.

The company serves large and medium-sized circulating fluidized bed boilers in the power industry. The main materials are: high-strength wear-resistant refractory castables, wear-resistant corundum plastics, self-flow wear-resistant corundum castables, medium-heavy and micro-expandable plastics, lightweight thermal insulation Concrete, high-performance high-alumina castables, high-temperature binders, high-temperature cement and plastering materials, various ramming materials, high-strength wear-resistant corundum bricks, ladle breathable bricks, silicon carbide bricks, intermediate frequency furnace linings, special-shaped wear-resistant refractory bricks, There are more than 160 kinds of amorphous products and shaped products in 20 series such as thermal insulation bricks, and the products sell well in all provinces, municipalities, autonomous regions and overseas. At the same time, the company has established a strong construction team to ensure the high-quality use of the products.

Previous: What reasons will affect the service life of the intermediate frequency furnace lining?

下一条: Introduction to the construction of furnace lining ramming material

Related Industry Knowledge

- Features and Benefits of Coil Clay

- What are the advantages of a good furnace lining

- Misunderstandings in the use of ramming materials in intermediate frequency furnaces

- Phenomenon analysis of failure of argon blowing of ladle permeable bricks and how to improve the rate of argon blowing

- Where is the consumption reduction and energy saving of breathable bricks reflected?

- How to improve the service life of intermediate frequency furnace lining

- Reasons for damage to intermediate frequency furnace lining and how to solve them

- The performance and advantages of breathable brick

- Analysis of Structural Characteristics of Dispersive Breathable Bricks

- The intermediate frequency furnace charge knotting process needs to pay attention to details sharing

- What reasons will affect the service life of the intermediate frequency furnace lining?

- What should be paid attention to in material selection of intermediate frequency furnace charge

- Ramming material manufacturers tell you how to improve the crack resistance of explosion-proof refractory castables

- Importance and characteristics of raw material structure of intermediate frequency furnace charge

- How to protect the lining of the intermediate frequency furnace

- What are the useful explosion-proof agents in unshaped refractories

- How to correctly construct the ramming material in the intermediate frequency furnace

- What are the special advantages of using coil insulating glue?

- Furnace lining manufacturers tell you the operation steps of the oven

- Analysis of Corrosion Phenomenon of Furnace Surface Lining