Refractory-Aluminum Refined Breathable Brick

Refractory-Aluminum Refined Breathable Brick

Introduction of refractory fiber paste

Refractory fiber paste is an all-round refractory material, which can form many complex shapes, like a high-temperature mold coating agent. It can also be used to form a refractory structure by sticking. Its formation is a refractory fiber with moisture. And it is a bond of high temperature. At high temperature, it forms a refractory material with hardness and thermal insulation, which is not in a wet state in the molten aluminum soup.

Refractory fiber paste is generally used for casting nozzles, risers (such as piston mold risers), shoe mold covers, and repairing of some crucible furnaces on aluminum alloy castings. Therefore, it is usually required that the thermal insulation performance of the adhesion of the refractory fiber paste is better, so as to prevent the refractory fiber paste from falling off and the instability of the flow of the riser aluminum soup, resulting in the resulting product becoming a defective product.

The characteristics of refractory fiber paste (refractory mud)

1, good plasticity, convenient construction; 2, high bonding strength, strong corrosion resistance; 3, high refractoriness, up to 1650 degrees Celsius ~ 50 degrees Celsius; 4, good slag resistance; 5, good thermal spalling.

Application of refractory mud

Refractory clay is used in coke ovens, glass kilns, blast furnace hot blast stoves, and other industrial kilns. Applications include: metallurgy, building materials, machinery, petrochemicals, glass, boilers, electricity, steel, cement, etc.

Refractory fiber paste classification

According to the material, it can be divided into clay, high alumina, siliceous and magnesia refractory mud, etc.

It is composed of refractory powder, binder and admixture. Almost all refractory raw materials can be made into powder for preparing refractory clay. It is made of refractory clinker powder and appropriate amount of plastic clay as binder and plasticizer. It is called ordinary refractory clay, its strength at room temperature is low, and it has higher strength when it forms ceramic bonding at high temperature. Chemically bonded refractory clay with hydraulic, gas-hardening or thermosetting bonding materials as the binding agent is lower than the formation temperature of ceramic bonding. Before a certain chemical reaction occurs, it hardens.

The particle size of refractory fiber paste (refractory mud) varies according to the requirements of use, and its limit particle size is generally less than 1mm, and some are less than 0.5mm or finer.

The material of the refractory mortar should be considered consistent with the material of the refractory products of the masonry. In addition to being used as a joint material, the refractory mortar can also be used as a protective coating for the lining by smearing or spraying.

Characteristics and application of refractory mud

1, good plasticity, convenient construction; 2, high bond strength, strong corrosion resistance; 3, high refractoriness, up to 1650 degrees Celsius ~ 50 degrees Celsius; 4, slag resistance

Good invasiveness; 5. Good thermal spallability. Refractory clay is mainly used in coke ovens, glass kilns, blast furnace hot blast stoves, and other industrial kilns. Application industries

There are: metallurgy, building materials, machinery, petrochemicals, glass, boilers, electricity, steel, cement, etc.

type

There are many kinds of refractories, which are usually divided into ordinary refractories (1580-1770 degrees Celsius), refractories (1770-2000 degrees Celsius) and super-grade refractories (above 2000 degrees Celsius) according to their refractoriness; Refractory materials and basic refractories. In addition, there are refractories used for special occasions. Now the definition of refractories does not only depend on whether the refractoriness is above 1580 degrees Celsius. At present, refractories generally refer to metallurgy, Inorganic non-metallic materials lining petrochemical, cement, ceramics and other production equipment.

Advantages: It is a gray-white refractory clay that can be molded by steaming.

Reduce the temperature drop of molten metal; do not wet aluminum, do not wet zinc; easy to operate; dry with a burner after steaming.

Application: DCT-1150 refractory fiber paste is suitable for:

1, runner funnel lining, shunt plate for continuous casting or horizontal casting.

2. Lining of heat treatment furnace.

3. The lining material of the batching furnace.

4. Gravity casting and pouring riser area.

5, the lining of ladle, spoon, etc.

6, In fact, it is suitable for any part that requires a small temperature drop.

7 How to use

First dip the mud spoon in water to avoid sticking to the refractory material, spread the refractory mud on the surface of the metal or refractory material to the required thickness and smooth the surface. more than 3 hours.

Related News

- Introduction of construction method of ramming material in intermediate frequency furnace

- How to choose the material of furnace lining

- The difference between rammer and castable

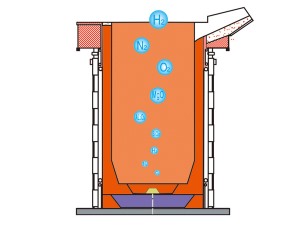

- Application direction of intermediate frequency furnace refining

- Introduction to the construction method of dry ramming material

- Do you know the production process and control points of breathable bricks?

- The application of argon blowing technology at the bottom of the intermediate frequency furnace

- Method for prolonging service life of intermediate frequency furnace lining

- In addition to diffused breathable bricks, there are those types of breathable bricks

- What are the advantages of coil cement

- Learn the basics of refractory materials through breathable bricks

- 4 main reasons for the damage of breathable bricks for ladle

- Analysis of the methods to improve the physical and chemical properties of ladle breathable bricks

- What are the requirements for the production materials of breathable bricks?

- The method and attention problems of carbon increase in intermediate frequency furnace

- Common problems in the application process of diffused breathable bricks

- What are the requirements for manufacturing materials of breathable bricks?

- Analysis of Characteristics of Refined Ladle Dispersion Type Breathable Bricks

- Two common methods of lining the intermediate frequency furnace

- What are the key points for the selection of intermediate frequency furnace lining materials? Do you really know?