The intermediate frequency furnace repair material is a plastic repair material that uses high-quality alumina as the main raw material and special chemical raw materials as the binder. The intermediate frequency furnace repair material has good anti-stick slag and corrosion resistance It is also very convenient, it is widely used in the repair of medium frequency induction furnace mouth, furnace lining, running bag and other industrial furnaces.

1. Precautions before opening the furnace

The intermediate frequency electric furnace must be checked for electrical equipment, water cooling system, inductor copper pipes, etc. before the furnace is opened. The furnace can only be opened when these equipments are in good condition to ensure the safety of heat treatment. Personnel who are specially responsible for power transmission and furnace opening, and the responsible personnel shall not leave their posts without authorization, and the external conditions of the inductor and the crucible must be supervised during work to prevent someone from touching the inductor and cable after the power supply, affecting the operation of the intermediate frequency electric furnace. normal operation or a safety accident occurs.

2. Precautions after opening the furnace

After the intermediate frequency electric furnace is started, when charging, the charge should be checked to avoid mixing inflammable and explosive and other harmful substances. After the molten liquid is filled to the upper part, it is not allowed to add larger blocks; in order to avoid explosion accidents, it is necessary to ensure that the pouring site and the pit in front of the furnace are free of water and obstacles; and two people are required to cooperate when pouring. The remaining molten steel can only be poured at the designated location, and cannot be poured everywhere.

3. Precautions for maintenance

When maintaining the intermediate frequency electric furnace, the intermediate frequency generator room should be kept clean, and the stacking of flammable and explosive items is strictly prohibited. Repair the furnace with excessive melting damage in time, and avoid iron filings and iron oxide when repairing the furnace. Mix in to ensure the density of the crucible.

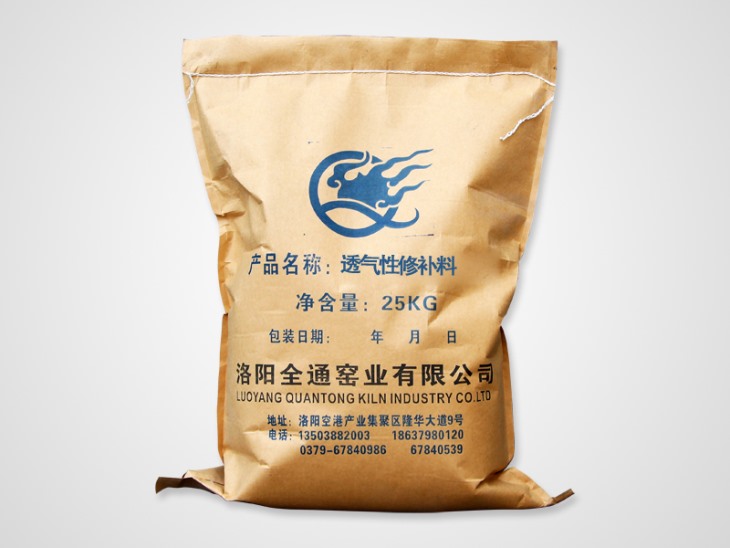

The main business of all kilnsIntermediate frequency furnace lining, intermediate frequency furnace charge and other products, welcome new and old customers to come to consult.