The high temperature performance of the medium frequency furnace bottom blown breathable brick mainly depends on the physical, chemical properties and mineral composition of the refractory materials used.Blowing argon at the bottom of the intermediate frequency furnaceBreathable bricks have been widely used.

Application of Gas Diffuser - Refining Technology of Intermediate Frequency Induction Furnace

Through the use of gas diffusers, we have summed up the refining technology of intermediate frequency induction furnaces, so that ordinary intermediate frequency induction furnaces can be transformed from "chemical steel" to steelmaking. In many cases, the quality of molten steel (Taijin) reaches AOD furnaces, LF refining Furnace, VD vacuum degassing furnace refining quality level.

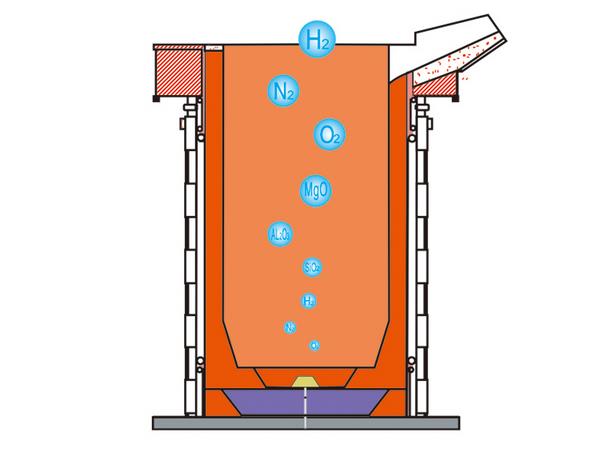

The required gas (such as high-purity argon) is sent to the molten steel through the gas diffuser, and after a certain amount and time of flow 8, it can reduce the inclusions (such as Sio2, Al2O3, MgO, etc.). And 【O】【 The effect of N] [H] content, there are special requirements such as decarburization, argon\/oxygen mixed gas can be blown in, which can reduce the amount of carbon in a certain range, and nitrogen can be blown in to increase ammonia when it encounters nitrogen steel.

\u003Ci>工作原理感应炉内吹入氩气精炼过程是在钢液熔清后.\u003C\/i> \u003Cb>Working principle The refining process by blowing argon into the induction furnace is after the molten steel is melted.\u003C\/b>\u003Ci>进行预脱氧完成后,取样分析后,将高纯度氩气通过安装在炉子底部的气体扩散器导入钢液,当氩气通过气体扩散器后,因分散度较高,形成了具有较大上升速度的微小气泡流,无数的气泡通过钢液将会产生精炼作用.钢液内部每个氩气泡就是一个小的"真空室",在氩气泡里不合H,O,N等气体.\u003C\/i> \u003Cb>After the pre-deoxidation is completed, after sampling and analysis, high-purity argon gas is introduced into the molten steel through the gas diffuser installed at the bottom of the furnace. The flow of tiny bubbles, countless bubbles will produce refining effect through the molten steel. Each argon bubble inside the molten steel is a small "vacuum chamber", and there is no H, O, N and other gases in the argon bubble.\u003C\/b>\u003Ci>也就是说氩气泡里面这些气体的分压力等于零.当分压力变很高的氩气泡,穿过钢液时,呈溶解状态存在的【H】【O】【N】和非溶解状态存在的c0等均会自动地进入氩气泡内,并随着气泡上升而溢出.\u003C\/i> \u003Cb>That is to say, the partial pressure of these gases in the argon bubble is equal to zero. When the partial pressure of the argon bubble becomes very high, when it passes through the molten steel, [H] [O] [N] exists in a dissolved state and c0 exists in a non-dissolved state, etc. All will automatically enter the argon bubble and overflow as the bubble rises.\u003C\/b>\u003Ci>从而达到脱气的目的.\u003C\/i> \u003Cb>So as to achieve the purpose of degassing.\u003C\/b>

\u003Ci>精炼后钢的质量,纯净度大大提高,精炼前后的夹杂物对比明显降低,气体含量大大减少.\u003C\/i> \u003Cb>The quality and purity of the steel after refining are greatly improved, the contrast of inclusions before and after refining is significantly reduced, and the gas content is greatly reduced.\u003C\/b>\u003Ci>现举例对比如下\u003C\/i>\u003Cb>The example is compared as follows\u003C\/b>

1. Inclusions: Microscopic evaluation method for non-metallic inclusions in steel GB10561-2005

project | A | B | C | D |

Sulfide | Alumina | Silicate | Globe oxide | |

Average before refining | 1.8class | 1.7class | 1.5class | 2.1class |

Average after refining | 0.55class | 0.64class | 0.5class | 0.67class |

average decreasepercentage | 69 | 62 | 67 | 68 |